Did you know your microwave oven can heat leftovers up to 80 times faster than a conventional oven? This everyday appliance relies on a science-driven process that turns electromagnetic energy into heat—but most people never learn how it actually happens.

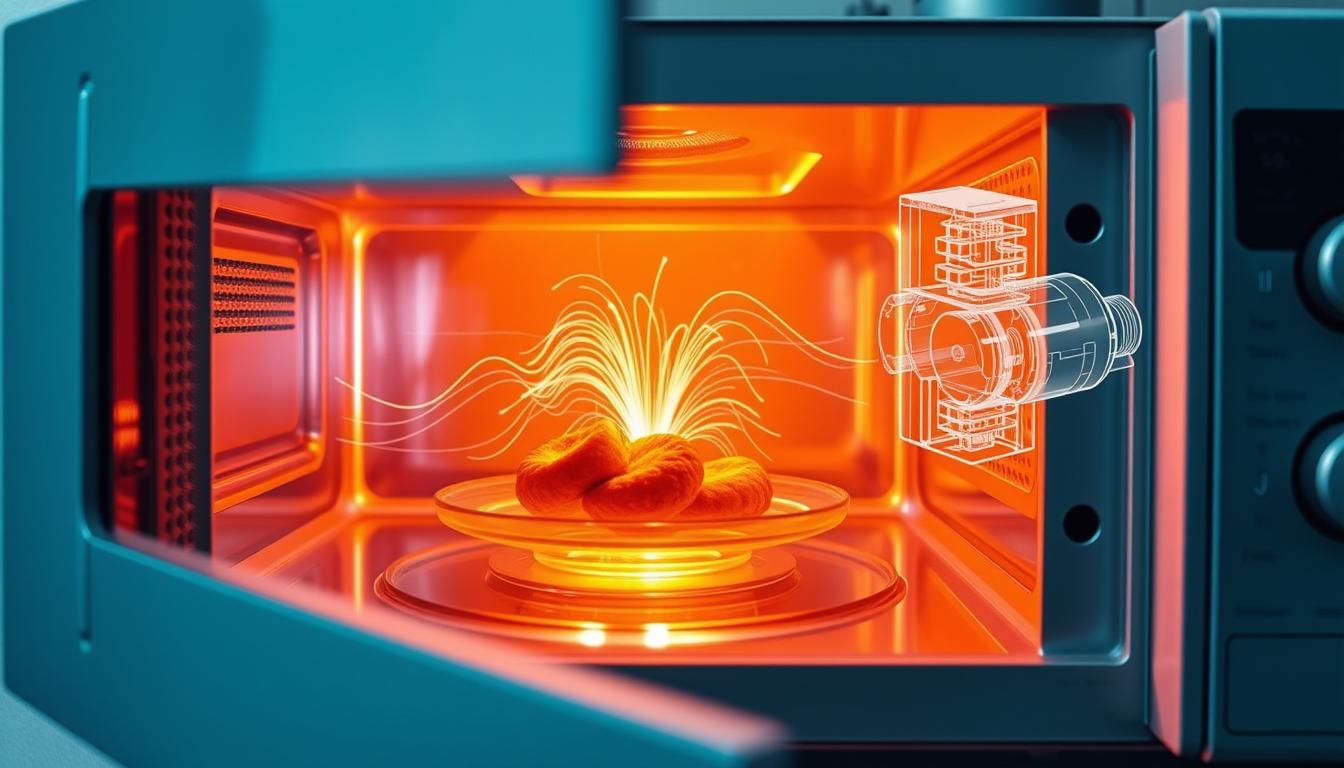

At its core, this method uses 2.4 GHz electromagnetic waves to agitate water molecules in food. Unlike stovetops or ovens, which heat air or surfaces first, microwaves target molecules directly. Water’s unique “V” shape makes it perfect for this: the oxygen and hydrogen atoms create a natural electric charge imbalance.

When microwaves hit these molecules, they spin rapidly—millions of times per second. This motion generates friction, which produces heat almost instantly. Called dielectric heating, this principle skips the slow transfer of warmth from outside to inside. Instead, your burrito heats evenly from the center outward.

Key Takeaways

- Microwaves use 2.4 GHz electromagnetic waves to directly energize water molecules in food.

- Dielectric heating creates friction through rapid molecular rotation, bypassing traditional heat transfer.

- The process is energy-efficient because it skips preheating and focuses only on the food itself.

- Water’s natural dipole structure makes it ideal for absorbing microwave energy.

- This method reduces cooking time by targeting molecules instead of heating air or surfaces.

Understanding Microwave Heating Principles

Your kitchen’s most efficient appliance operates on principles borrowed from physics labs. At its heart lies a clever dance between electromagnetic radiation and the molecular structure of what you’re reheating.

Dielectric Heating and Water Molecules

Water’s unique “V” shape creates natural polarity – oxygen pulls electrons harder than hydrogen atoms. This imbalance makes water molecules act like microscopic magnets. When 2.4 GHz waves flood the cooking chamber, these molecules spin 2.5 billion times per second trying to align with the shifting electric field.

The resulting friction generates heat directly within your food. This explains why celery (95% water) heats faster than bread (35% water). Unlike stovetop cooking that warms surfaces first, dielectric heating works from the molecules food contains outward.

Electromagnetic Radiation in Cooking

Microwave energy uses non-ionizing radiation – it vibrates water molecules food without breaking chemical bonds. The waves penetrate about 1-1.5 inches into most dishes, creating uniform warmth. As physicist Percy Spencer discovered in 1945, this process skips the air-heating step entirely.

Your appliance’s frequency (2,450 MHz) is specially tuned. Lower frequencies wouldn’t spin molecules fast enough, while higher ones might overheat surfaces. This balance ensures efficient cooking while preserving nutrients better than boiling.

The Role of the Magnetron in Microwave Ovens

What powers your appliance’s ability to reheat meals in seconds? At its core lies the magnetron—a vacuum tube that converts electricity into radio waves. This technology traces its roots to 1940s radar systems, where engineers first harnessed its unique properties.

How the Magnetron Generates Microwaves

The magnetic field inside the tube bends electron paths using the Lorentz Force. Electrons spiral around the cathode instead of moving straight to the anode, creating rotating energy. This motion resonates through copper cavities, producing 2.45 GHz radio waves.

Early models filled entire rooms. Japanese engineer Kinjiro Okabe revolutionized the design in 1927 with split-anode technology. His improvements made magnetrons compact enough for practical use.

“I felt a strange warmth in my pocket—the radar waves had melted my chocolate bar.”

Evolution from Radar to Everyday Cooking

World War II accelerated magnetron development in the United States for military radar. Post-war engineers repurposed this tech after noticing its heating effects. The first commercial unit weighed 750 pounds and cost $5,000—equivalent to $60,000 today.

| Feature | Early Magnetrons (1940s) | Modern Magnetrons (1970s) |

|---|---|---|

| Size | 24″ diameter | 4″ diameter |

| Cost | $2,500 | $15 |

| Applications | Military radar | Home kitchens |

By the 1970s, Japanese manufacturers perfected mass production. This slashed prices, making microwave ovens accessible to households. Today’s models use the same fundamental physics—just smarter and safer.

Safety Features and Microwave Oven Regulations

Your microwave oven contains multiple safeguards ensuring protection during daily use. Strict federal guidelines govern every aspect of design and operation.

FDA Standards and Radiation Safety

Since 1971, the FDA enforces radiation limits through 21 CFR 1030.10. This rule caps leakage at 5 milliwatts/cm² when measured 2 inches from the oven surface. Independent labs verify compliance through 200+ annual tests.

Energy exposure drops rapidly with distance. Standing 20 inches away reduces intensity to 1% of the 2-inch measurement. These margins make modern units safer than sunlight exposure during typical use.

Interlock Systems and Leakage Prevention

Two separate locking mechanisms instantly halt microwave production if doors open mid-cycle. A third monitor shuts down the appliance if either system fails. This triple-layer protection prevents accidental radiation release.

Damaged door seals or misaligned latches compromise safety. Regularly inspect these parts for wear. Replace cracked glass or warped cavity surfaces immediately to maintain optimal performance.

Optimizing Your Microwave Oven Usage

Mastering your appliance’s settings transforms quick meals into perfectly cooked dishes. Modern units offer precision controls that adapt to different foods and tasks. Let’s explore how to harness these features effectively.

Adjusting Power Levels and Cooking Time

Most microwave ovens provide 10 power settings. Use 50% power for reheating leftovers to avoid rubbery textures. Defrost modes operate at 20-30% intensity, gently thawing meats without partial cooking edges.

Dense items like potatoes need longer time at medium power. Stir liquids halfway through heating to prevent superheating. For 1,200-watt models, reduce cooking durations by 15% compared to 1,000-watt units.

Effective Use and Maintenance Tips

Arrange foods in a ring pattern for even exposure. Cover dishes with vented lids to retain moisture. Wipe spills immediately using warm water and mild detergent—abrasive cleaners scratch cavity surfaces.

Test door seals monthly: close the oven on a dollar bill. If it slips out easily, replace the gasket. Schedule professional servicing if sparks appear or turntables malfunction.

| Cleaning Solution | Safe Surfaces | Avoid |

|---|---|---|

| Vinegar + Water | Interior walls | Metal scrubbers |

| Baking Soda Paste | Turntable | Bleach products |

How Microwave Heating Works: Science Behind the Process

Long before reheating leftovers became routine, dielectric heating transformed manufacturing processes. This energy-efficient method now powers your kitchen appliance through precise molecular interactions.

Targeted Energy Transfer Explained

When molecules in food vibrate at 2.4 billion cycles per second, they create thermal energy through friction. Water’s natural polarity makes it the primary target—each molecule acts like a microscopic rotor responding to electromagnetic pushes. Fats and sugars absorb less energy, explaining why celery heats faster than chocolate.

The process converts wave energy directly into heat without altering chemical structures. Since radiation stops when the oven turns off, your meal remains non-radioactive. This selective heating mechanism explains why microwave-safe containers stay cool while their contents steam.

Beyond the Kitchen: Industrial Innovations

Manufacturers adopted dielectric principles decades before home appliances existed. Timber mills use it to dry wood three times faster than air curing. Textile factories bond synthetic fibers using this method, achieving uniform adhesion without surface burns.

In Japan’s Akita Prefecture, artisans create curved Mage-wappa tableware by softening wood with steam from internal heating. This technique preserves grain patterns that conventional bending methods destroy. Such applications demonstrate how controlled molecular vibration solves diverse engineering challenges.

Common Microwave Cooking Settings and Modes

Modern microwave ovens offer more than just quick reheating—they’re multi-functional hubs for diverse culinary tasks. Advanced models feature specialized programs that adapt to specific ingredients and desired outcomes. Let’s explore how these intelligent settings enhance your kitchen efficiency.

Defrost, Convection, and Sensor Settings

Defrost modes operate at 20-30% power to gently thaw frozen items. This prevents outer edges from cooking while inner layers remain icy—ideal for meats and baked goods. Convection models combine microwave energy with heated air circulation, achieving crispy textures impossible with standard settings.

Sensor technology revolutionizes convenience. Infrared detectors measure steam released from food, automatically adjusting cooking time and intensity. Forgot to set the timer? The oven stops when your lasagna reaches optimal internal temperature.

Steam and Specialized Cooking Modes

Steam functions preserve nutrients in vegetables and proteins better than boiling. Built-in vessels distribute vapor evenly, locking in flavors without sogginess. Premium units go further with dedicated programs:

- Air frying: Crunchy fries using 80% less oil

- Baking: Evenly risen cakes with golden crusts

- Slow cooking: Tender stews simmered over hours

These innovations transform your appliance into a compact kitchen station. Match settings to your ingredients—steam for delicate fish, convection for roasted vegetables, sensor modes for unpredictable leftovers.

Microwave Oven Materials and Cookware Safety

Your container choices directly impact cooking efficiency and safety. Certain materials interact with electromagnetic waves in ways that affect both your meal and appliance longevity.

Choosing Microwave-Safe Cookware

Glass and ceramic dishes work best unless they contain metallic paints. Handmade pottery often includes air bubbles that can crack under rapid heating. Always check for manufacturer labels confirming microwave compatibility.

Plastics require extra caution. Only use containers marked “microwave-safe”—others may leach chemicals like BPA into food when heated. Warped or discolored plastic should be discarded immediately, even if previously approved.

Metal containers and foil create dangerous sparks by reflecting waves. This reflection causes uneven cooking and can damage your oven’s interior. For defrosting, use Ziploc bags explicitly rated for microwave use.

| Material Type | Safe for Microwave | Notes |

|---|---|---|

| Glass | Yes | Avoid lead crystal |

| Ceramic | Usually | Check for metallic glaze |

| Plastic | Labeled only | Discard if warped |

| Metal | No | Causes arcing |

| Ziploc Bags | If specified | Leave partially open |

Test questionable containers: Heat a cup of water beside the empty dish for 1 minute. If the container stays cool, it’s likely safe. Replace cracked or chipped dishes—flaws trap bacteria and create hot spots.

Historical Development and Future Innovations

The evolution of microwave tech is a tale of accidental discovery and smart engineering. What began as military radar research now sits on your countertop, reshaping how kitchens operate worldwide.

The Journey From Early Designs to Modern Models

Commercial microwave ovens debuted in 1947 as refrigerator-sized units costing $5,000. These early models were also used exclusively in restaurants and labs. Japanese engineers revolutionized the field in the 1970s by replacing bulky alnico magnets with compact ferrite versions.

This breakthrough slashed production costs by 98%. By 1975, countertop ovens became affordable for households. The same dielectric energy principles once also used for drying lumber now reheated TV dinners.

Emerging Trends in Microwave Technology

Today’s innovations focus on precision and sustainability. New microwave ovens integrate AI sensors that adjust heating elements based on food density. Some prototypes use 5G frequencies for faster cooking cycles.

Manufacturers are exploring eco-friendly designs. These models recover waste energy to power LED displays. As tech advances, your kitchen appliance keeps rewriting the rules of efficient cooking.