A single grease flare-up can engulf an entire commercial cooking area in under 30 seconds. Traditional water-based solutions often worsen these emergencies, as oil-based flames spread faster when doused improperly. This reality demands specialized infrastructure designed for high-heat environments where ordinary methods fail.

Effective protection relies on understanding the three elements sustaining flames: fuel sources (like cooking oils), oxygen, and ignition points. In fast-paced culinary spaces, standard sprinklers risk creating explosive steam bursts when contacting hot grease. Modern alternatives use precise chemical agents that smother flames without spreading hazardous materials.

Your operation requires equipment that detects threats through thermal sensors while allowing manual override capabilities. These setups integrate automatic gas line shutoffs and electrical disconnects – critical features preventing secondary explosions. Regular maintenance by certified technicians ensures compliance with NFPA 96 standards and operational readiness during crises.

Key Takeaways

- Specialized infrastructure outperforms water-based solutions for grease-related emergencies

- Chemical agents prevent flame spread more effectively than traditional methods

- Integrated safety protocols disable utilities automatically during incidents

- Compliance with national fire codes requires professional installation and upkeep

- Rapid detection systems minimize operational downtime and repair costs

Understanding the Need for Kitchen Fire Suppression Technology

Statistics reveal a harsh reality for food service establishments: cooking areas face unique dangers that demand tailored responses. The NFPA reports $165 million in annual property losses from restaurant incidents, with 60% originating near heat sources like fryers and griddles.

The Risks in Commercial Kitchens

Your cooking appliances create constant ignition points. When oils reach 600°F+ temperatures, standard extinguishers become ineffective. Water-based methods risk spreading flames, while improper techniques could trigger explosions.

Why Standard Methods Fail

Grease-related incidents require temperature-reducing agents like K-1 compounds. These specialized formulas cool burning oils below 450°F – the critical threshold where reignition becomes impossible. Properly installed hood-based systems localize damage, protecting ventilation infrastructure and adjacent equipment.

Investing in certified protection cuts repair costs by up to 80% compared to rebuilding after uncontrolled incidents. More importantly, it safeguards your team and customers from life-threatening situations.

Exploring Key Components of Suppression Systems

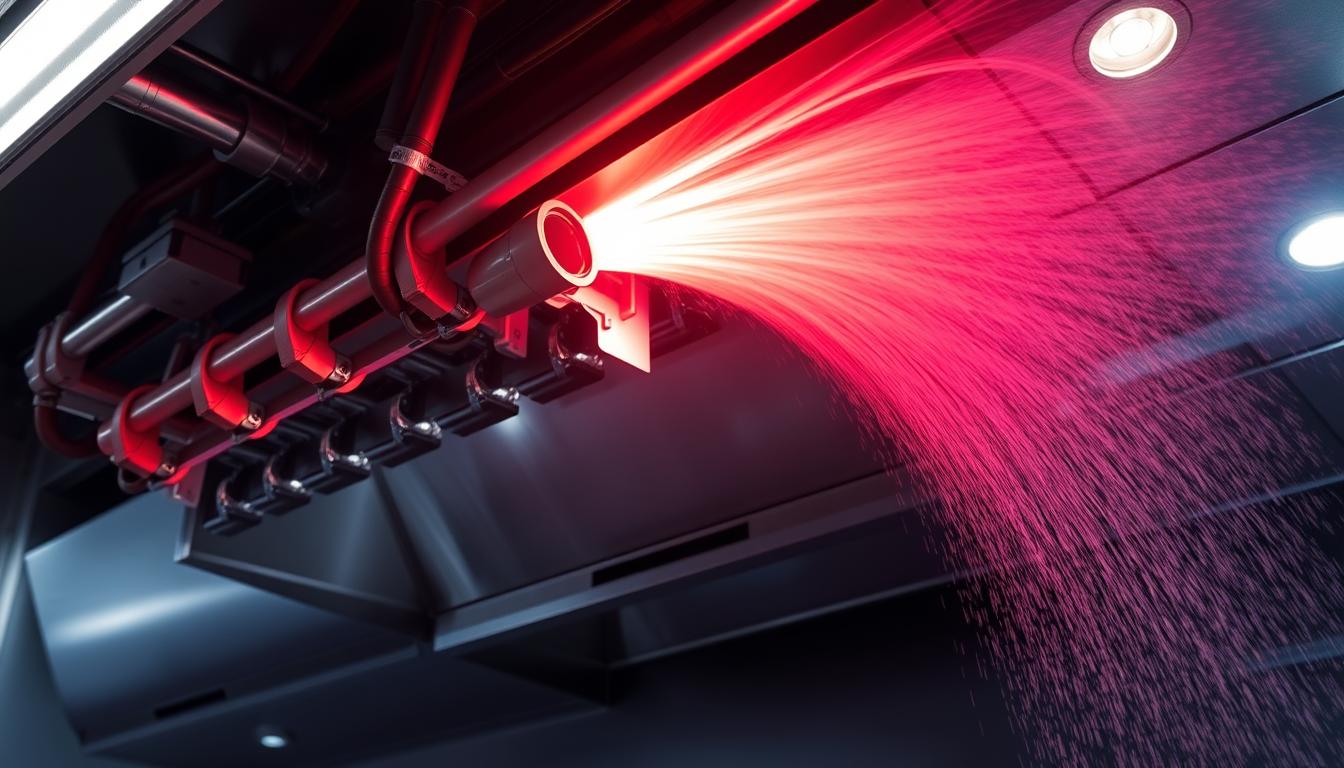

Modern cooking environments demand specialized protection mechanisms that act faster than human reflexes. These setups combine advanced detection methods with chemical reactions designed to neutralize threats within seconds.

Automatic Versus Manual Activation Features

Your setup uses thermal sensors that trigger when temperatures exceed 500°F. This automatic response works 24/7, even during staff shortages. Manual pull stations let trained personnel activate protection immediately if they spot flames before sensors react.

| Activation Type | Trigger Method | Response Time | Best Use Case |

|---|---|---|---|

| Automatic | Heat detection sensors | 3-8 seconds | Unattended equipment |

| Manual | Pull station activation | Instant | Visible flames |

Role of Chemical Agents and Saponification

Specialized liquids replace water in these setups. When discharged, they mix with hot oils to form a foam barrier. This reaction – called saponification – seals fuel sources from oxygen while cooling surfaces below ignition points.

Maintenance and Compliance With NFPA 96 and UL Standards

Monthly inspections verify nozzle cleanliness and gas valve functionality. Annual tests ensure cylinders maintain proper pressure levels. Only UL 300-certified technicians should service equipment, as improper handling voids warranties and compromises safety.

Implementing Your Kitchen Fire Suppression System

Proper setup begins with understanding your unique operational needs. Cooking environments vary widely, requiring tailored approaches to address grease buildup and heat sources effectively.

Customizing Protection for Your Space

Evaluate appliance types and workflow patterns when selecting equipment. Certified technicians should assess ventilation layouts and fuel sources to match components with your risks. This ensures compliance with regional codes while addressing unlisted equipment exceptions.

Expert Installation Matters

Always use professionals trained in UL 300 standards for setup. They’ll verify nozzle placement and integrate automatic shutoffs with gas lines. Post-installation, schedule bi-annual inspections to maintain peak performance.

Document all service visits and keep activation manuals accessible. Pair your setup with staff training on emergency protocols to create layered protection. Regular upkeep prevents 73% of equipment failures during critical moments.