Every 37 seconds, industrial systems across America face pressure spikes that could rupture pipelines or explode storage tanks. Relief valves quietly neutralize these threats through precise engineering principles. These safety mechanisms balance spring tension against fluid forces, acting only when critical thresholds get breached.

You might compare their operation to a highly trained security team. They stand ready 24/7 but spring into action only during emergencies. When system pressures exceed safe limits, stored energy gets redirected through calculated openings. This prevents catastrophic failures while maintaining operational continuity.

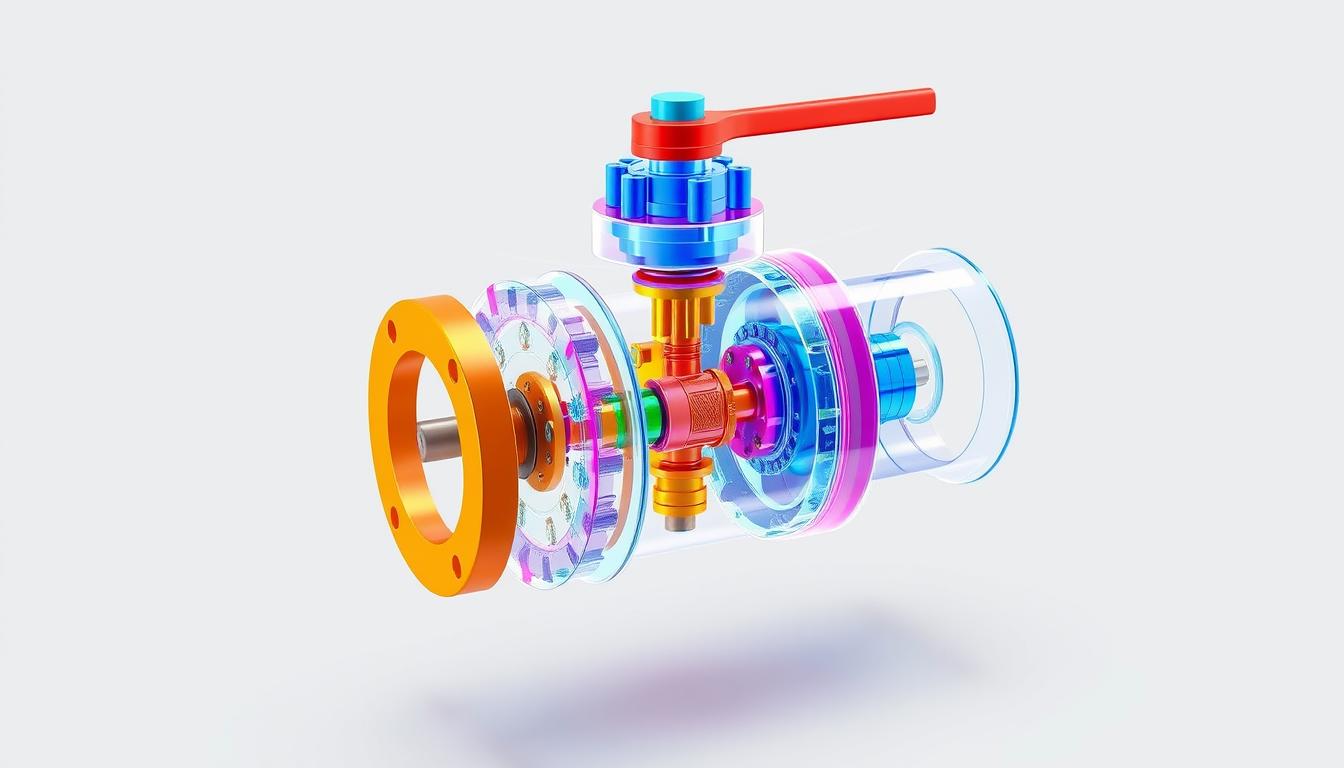

Modern designs combine mechanical precision with fluid dynamics mastery. Spring-loaded discs respond faster than human operators ever could. Automatic resealing occurs once equilibrium restores, minimizing downtime. This seamless integration with industrial controls makes them indispensable safety components.

Understanding their physics reveals why they outperform digital safeguards during power outages. Unlike electronic systems, relief valves require no external energy source. Their fail-safe operation stems from fundamental force relationships – a marriage of simplicity and reliability that protects billions in equipment daily.

Key Takeaways

- Spring-loaded mechanisms activate automatically during pressure emergencies

- Fluid dynamics principles enable precise pressure redirection

- Mechanical operation ensures functionality without power sources

- Critical prevention of equipment damage and workplace hazards

- Continuous protection with automatic reset capabilities

Fundamentals of Pressure Relief Valves and Safety

Behind every secure fluid system lies a silent protector against catastrophic failure. These devices balance precise engineering with fail-safe operation, intervening only when other controls falter.

How Pressure Relief Valves Work

Spring-loaded mechanisms maintain equilibrium between stored energy and containment forces. During normal operation, calibrated springs keep seals tightly closed. When internal forces exceed preset limits, the system redirects excess energy through controlled openings.

This automatic response occurs through direct fluid contact, requiring no external power. Engineers design these components to create predictable escape routes for dangerous buildups. Proper sizing ensures compatibility with diverse media – from steam to corrosive chemicals.

The Importance of Safety in Fluid Systems

Modern industrial operations use layered protection strategies. While regulators manage routine fluctuations, relief valves act as final barriers against disaster. Consider this comparison of safety measures:

| Primary Control | Secondary Safeguards | Final Protection |

|---|---|---|

| Pressure regulators | Alarm systems | Relief valves |

| Manual shutoffs | Redundant pumps | Rupture discs |

| Automated controls | Pressure sensors | Emergency vents |

Properly maintained valves prevent equipment damage and workplace injuries. They activate only when essential, preserving operational continuity while guarding against human error and mechanical failures. Regular testing ensures readiness for unexpected pressure surges.

Exploring The Physics of Pressure Release Valves

Industrial systems operate under constant threat from unseen energy buildups. When containment forces battle stored potential, spring-loaded mechanisms become the ultimate fail-safe. These devices transform theoretical physics into life-saving reality through precise mechanical responses.

Core Physical Principles: Pressure, Flow, and Energy

Pascal’s law governs critical moments in fluid containment systems. Confined liquids transmit force equally, pushing against calibrated springs until reaching activation thresholds. This fundamental principle ensures predictable responses during emergencies.

Energy conversion occurs instantly when mechanisms trip. Potential energy becomes kinetic flow through calculated openings, like water bursting through a dam’s spillway. Engineers design these discharge paths using flow rate equations that account for viscosity and temperature variations.

Integration with System Controls

Modern plants pair mechanical safeguards with digital monitoring. Sensors track upstream conditions while algorithms predict pressure trends. This combination allows proactive maintenance before activation becomes necessary.

Three critical factors ensure proper integration:

- Matching response times between electronic alerts and mechanical releases

- Calibrating set points below secondary containment limits

- Maintaining failsafe operation during power outages

“The beauty lies in the marriage of simple mechanics and complex systems,” observes a senior safety engineer. These components work like circuit breakers for fluid networks – silent until needed, decisive when activated.

Industrial Applications and Design Considerations

Complex process networks demand precision-engineered safeguards. Modern facilities integrate pressure relief valves into every critical junction, from reactor feed lines to analytical instrument clusters.

Chemical Plants and Refinery Systems

Corrosive media and extreme temperatures dictate specialized valve designs. Nickel alloys and polymer coatings protect mechanisms in sulfuric acid service. Refinery flare systems require rapid-response models that handle 1,500+ psi surges.

Online analyzers demonstrate why customization matters. These $250,000+ instruments need low-set relief valves reacting to 5 psi fluctuations. Containment models prevent toxic leaks by routing discharges to scrubbers instead of atmosphere.

Hazard Mitigation in High-Pressure Environments

Process engineers follow strict placement rules for maximum protection. Valves mount within 10 feet of protected equipment in gas service. Liquid systems allow 50-foot spacing due to slower pressure wave propagation.

| Application | Valve Type | Set Pressure Range | Discharge Handling |

|---|---|---|---|

| Chlorine processing | Sealed bellows | 50-300 psi | Scrubber system |

| Steam headers | Open spring | 150-1,200 psi | Atmospheric vent |

| Hydrogen storage | Pilot-operated | 2,500-5,000 psi | Flare stack |

Three factors drive system design choices: media corrosivity, peak pressure scenarios, and failure consequences. ASME Section VIII mandates annual testing for valves in refinery service.

Conditions that Trigger Pressure Relief Activation

Unexpected pressure surges often start with preventable scenarios. Human mistakes and equipment degradation create dangerous situations where safety mechanisms become essential. Understanding these triggers helps prevent system failures before they occur.

Operational Errors and Component Wear

Mishandling equipment accounts for 43% of emergency activations. Imagine a technician opening valves out of sequence during maintenance. This mistake could send pressure builds racing through pipes faster than controls can respond.

Worn components worsen these risks. Seals in chemical processing systems degrade 60% faster when handling corrosive media. Metal fatigue from repeated pressure cycles eventually leads to regulation failures.

Contamination and Power Loss Scenarios

Foreign particles as small as 50 microns can disable primary controls. Dust ingress during filter changes often causes pressure may spikes that bypass regulators. These events demand immediate relief valve action.

Electrically-dependent systems face unique risks. When power fails during storms, backup generators need 12 seconds to engage. Relief valves become the last defense against catastrophic overpressurization in that critical window.

| Failure Cause | Contributing Factors | Mitigation Strategy |

|---|---|---|

| Valve misoperation | Inadequate training | Digital twin simulations |

| Seal degradation | Chemical exposure | Quarterly integrity tests |

| Sensor fouling | Dust accumulation | Redundant monitoring |

| Power disruption | Grid instability | UPS backup systems |

“Three factors determine emergency response success: detection speed, relief capacity, and maintenance frequency,” notes a refinery safety director. Regular testing cuts unplanned activations by 78% in high-risk facilities.

Predictive maintenance programs now use vibration analysis to spot worn components before failures occur. This proactive approach reduces unexpected shutdowns while maintaining safety margins.

Valves: Types, Mechanisms, and Operational Insights

Industrial safety hinges on matching valve designs to specific system demands. Two primary technologies dominate overpressure protection: spring-operated and pilot-operated mechanisms. Each offers distinct advantages for different operational scenarios.

Spring-Operated vs. Pilot-Operated Designs

Spring-loaded devices work like coiled guardians. Compressed springs hold seats closed until system forces overcome resistance. Conventional models suit general applications, while bellows-sealed versions handle backpressure challenges.

Pilot-operated alternatives function as precision commanders. A small control valve manages the main outlet, enabling faster response in high-flow systems. Snap-acting pilots deliver instant full openings during emergencies. Modulating types adjust gradually to match pressure fluctuations.

Advanced Safety Features and Alternatives

Modern upgrades boost reliability across valve types. Position indicators show real-time status, while remote sensors enable predictive maintenance. Lift-assist mechanisms reduce wear during repeated activations.

Three alternatives expand protection strategies:

- Rupture discs for single-use containment breaches

- Weighted valves in low-pressure systems

- Buckling pin devices for precise failure points

Seat geometry proves critical for consistent performance. Hardened alloys maintain seal integrity through thousands of cycles. Proper material selection prevents corrosion-induced leaks in chemical environments.

Valve sizing ranges from compact 0.5-inch inlets to industrial 8-inch connections. Each requires customized spring rates and flow calculations to ensure optimal operation. “Choose based on response speed needed, not just pipe diameter,” advises a refinery maintenance chief.

Technical Terminology and Certification Standards

Certification standards form the backbone of reliable pressure management systems. Mastery of precise terms ensures proper valve selection and compliance with life-saving regulations.

Key Terms: Set Pressure, Blowdown, and Full Lift

Set pressure determines when your safety mechanism activates. This critical threshold varies by application, ranging from 15 psi in cooling systems to 5,000 psi in gas compression.

Blowdown refers to the pressure drop needed for reseating. Most valves require 7-10% reduction below set pressure before closing. Full lift describes maximum disc movement, ensuring full flow capacity during emergencies.

Compliance with ASME and Other Industry Codes

ASME Boiler Code sections govern design and testing. Facilities using non-compliant valves risk fines exceeding $500,000 per violation. Compare major standards below:

| Standard | Scope | Key Requirement | Compliance Check |

|---|---|---|---|

| ASME I | Power boilers | Annual capacity tests | NB-18 stamp |

| ASME VIII | Pressure vessels | 3% overpressure test | UV stamp |

| API 526 | Flanged valves | Flow certification | QR code tracing |

| NBIC | Repair standards | Welder certification | R stamp |

National Board certification requires destructive testing on 1% of production valves. API 520 guides sizing calculations for hydrocarbon service. Proper documentation proves compliance during OSHA inspections.

Optimizing System Design for Safety and Efficiency

Optimizing fluid systems requires more than quality parts—it demands intelligent design foresight. Strategic placement of safety mechanisms works best when planned during initial layouts. This approach prevents costly retrofits while addressing multiple risk factors simultaneously.

Integrating Relief Valves with Pressure Regulators

System design thrives on complementary relationships between components. Pairing regulators with relief valves creates layered protection—one manages daily fluctuations, the other handles emergencies. This tandem setup maintains stable flow rates while readying instant responses to dangerous spikes.

Proper integration reduces strain on pumps and piping networks. Alignment between set points ensures smooth transitions from normal operations to crisis mitigation. Regular calibration checks keep both systems synchronized over time.

Enhancing System Reliability Through Design Best Practices

Simplified layouts outperform complex configurations in high-risk environments. Eliminating unnecessary fittings cuts potential leak points by 62% in typical fluid systems. Vibration-resistant mounts and thermal expansion joints further boost durability.

Three principles guide effective implementations:

- Cluster critical components within easy maintenance reach

- Use standardized parts to streamline repairs

- Allow clearance space for future upgrades

These strategies create resilient networks that withstand operational stresses while simplifying troubleshooting. Smart design choices made today prevent tomorrow’s catastrophic failures.