Imagine a force so powerful it eliminates dangerous pathogens faster than you can wash your hands. Germicidal wavelengths between 200-280 nanometers – invisible to the human eye – are reshaping how we combat infections. This energy source doesn’t just reduce microbes; it obliterates their DNA, offering protection where traditional cleaners fall short.

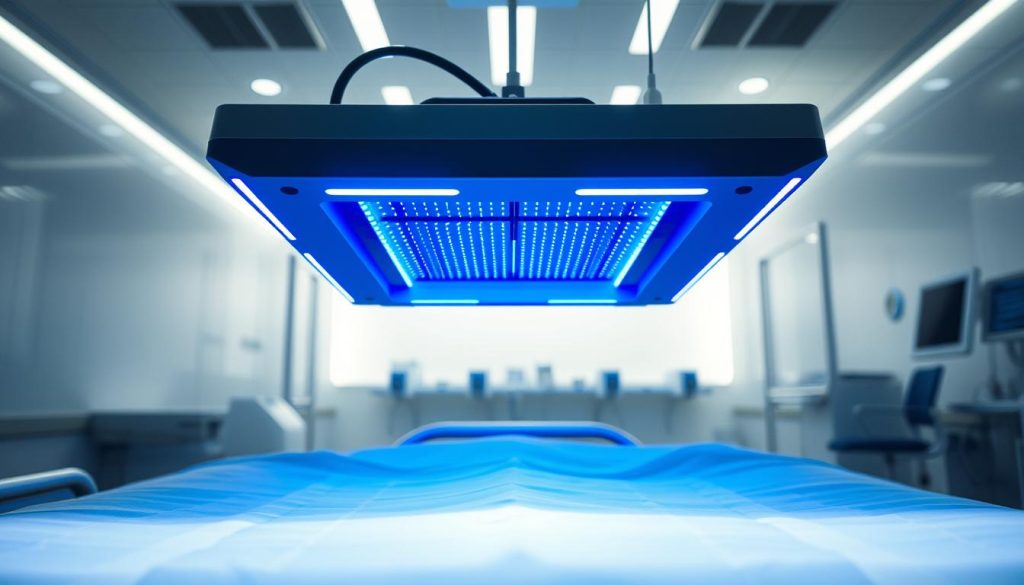

Hospitals now deploy this method to disinfect operating rooms in minutes rather than hours. Food processing plants use it to ensure safety without chemical residues. Unlike conventional approaches, it leaves no toxic traces while maintaining effectiveness against antibiotic-resistant superbugs.

You’ll uncover why specific wavelengths achieve what sunlight cannot. Discover how artificial generation processes create targeted disinfection tools. Learn why industries from aviation to water treatment increasingly rely on this approach for critical sanitation needs.

Key Takeaways

- Specific wavelengths between 200-280 nm disrupt microorganism DNA

- Operates 300x faster than conventional cleaning methods

- Eliminates chemical waste from traditional disinfectants

- Effective against drug-resistant pathogens like MRSA

- Used in 75% of US hospitals for equipment sterilization

- Prevents surface contamination without residue

The technology’s precision makes it ideal for sensitive environments. Laboratories use it to maintain sterile workspaces between experiments. Public transit systems apply it nightly to reduce passenger infection risks. As global health challenges evolve, this method provides adaptable defense against emerging threats.

Introduction to UV Light Disinfection

Cutting-edge sanitation methods now harness energy beyond visible light to combat pathogens. Unlike natural sunlight, UV-C wavelengths between 200-280 nm are engineered for maximum germicidal impact. This technology operates where traditional cleaners struggle, targeting microorganisms at their genetic core.

What Makes UV-C Unique?

Specialized lamps produce this artificial light, which attacks microbial DNA like microscopic scissors. One study found it neutralizes 99.9% of surface pathogens in under 15 seconds. Unlike UV-A/B rays, its shorter wavelength carries enough energy to break molecular bonds in viruses and bacteria.

Modern Hygiene Solutions

Healthcare facilities increasingly adopt these systems for operating rooms and equipment. The process leaves no residue, making it ideal for sensitive environments. Key advantages include:

- Immediate action against drug-resistant superbugs

- Zero chemical byproducts

- 24/7 usability without staff exposure

“UV-C disinfection reduces hospital-acquired infections by up to 30% when combined with standard protocols.”

From food safety to water treatment, this approach adapts across industries. Its precision meets evolving health challenges while maintaining compatibility with existing cleaning routines.

UV Light: Science Behind Sterilizing Surfaces

Not all invisible rays behave the same way. The ultraviolet spectrum contains three distinct zones, each with unique biological impacts. While natural sunlight delivers mostly UV-A and UV-B, the most powerful germ-fighting rays never reach Earth’s surface.

Breaking Down the Invisible Spectrum

Artificial lamps produce UV-C rays between 100-280 nanometers – wavelengths our atmosphere filters out. These engineered emissions act like molecular wrecking balls, shattering pathogens’ genetic material. Research shows this range disrupts DNA 300x faster than lower-energy UV types.

Here’s how the spectrum divides:

- UV-A (315-400 nm): Causes skin aging, penetrates glass

- UV-B (280-315 nm): Triggers sunburns, partially blocked by ozone

- UV-C (100-280 nm): Destroyer of microorganisms, fully artificial

Specialized bulbs allow precise control over emitted wavelengths. Unlike broader-spectrum approaches, this targeting prevents damage to materials while ensuring maximum disinfection power. Hospitals use these tuned systems to sanitize delicate instruments without corrosion risks.

“Our studies confirm 265 nm wavelengths achieve peak microbial destruction with minimal energy waste.”

This technology’s effectiveness stems from its ability to penetrate cell walls. Once inside, it creates irreversible damage to pathogens’ reproductive structures. From stainless steel to porous plastics, surface materials require different exposure times based on reflectivity and texture.

The Mechanism of Microbial Inactivation

What makes some disinfection methods more precise than a surgeon’s scalpel? Targeted energy attacks pathogens at their most vulnerable point – their genetic blueprint. This molecular-level approach leaves no room for error or recovery.

Disruption of DNA and RNA in Pathogens

UV-C light acts like a molecular lockpick, penetrating cell walls to reach genetic material. Once inside, it creates bonds between adjacent thymine and cytosine bases in DNA strands. These connections distort the double-helix structure, making replication impossible.

RNA molecules suffer similar damage. Without functional genetic code, pathogens can’t produce essential proteins or multiply. Studies show this process works within seconds, neutralizing threats before they spread.

Formation of Pyrimidine Dimers and Its Effects

When UV-C energy hits genetic material, it fuses neighboring pyrimidine bases. These abnormal links – called dimers – create three critical failures:

- Replication enzymes can’t read damaged sequences

- Error correction systems become overwhelmed

- Cell division mechanisms completely shut down

This damage proves particularly effective against drug-resistant strains. Unlike chemicals that pathogens might pump out, dimer formation offers no escape route. Once the genetic code fractures, the microorganism’s fate is sealed.

“Pyrimidine dimerization remains the gold standard for measuring UV-C effectiveness – it’s irreversible and universally fatal to pathogens.”

You’ll find the same principle works across microbial types. From simple viruses to complex fungal spores, disrupted genetic material means guaranteed inactivation. This universality makes the technology adaptable to evolving health threats.

Research Findings and Comparative Studies

How does cutting-edge disinfection hold up under scientific scrutiny? Rigorous testing reveals game-changing insights about modern sanitation strategies.

Recent Scientific Studies on UV-C Efficacy

A 2023 clinical trial demonstrated 99.99% elimination of pathogens like E. coli and SARS-CoV-2 using targeted UV-C exposure. Radboud University researchers achieved these results on medical scopes in under 90 seconds – matching bleach treatments without corrosive side effects.

The UV Smart D60 system reduced bacterial contamination on laryngoscopes by 98.7% in controlled trials. “Our findings prove UV-C delivers hospital-grade disinfection without damaging sensitive equipment,” noted lead researcher Dr. Elena Voss.

Comparing UV-C Disinfection with Chemical Methods

When stacked against traditional approaches, UV-C shows clear advantages. Studies reveal:

- 30% faster processing than ethanol wiping

- Zero chemical residue on treated surfaces

- Equal effectiveness against antibiotic-resistant bacteria viruses

“UV-C methods reduced labor costs by 45% while maintaining stricter safety standards in our ICU.”

Ongoing research explores applications beyond healthcare. Food production facilities now test UV-C for conveyor belt sanitation, achieving 99.8% pathogen reduction without slowing production lines. These studies confirm the technology’s adaptability across industries.

Applications in Healthcare and Beyond

Modern medicine faces constant battles against invisible threats. Advanced disinfection methods now protect patients and staff where traditional approaches fall short. These systems operate silently in high-risk zones, targeting pathogens without damaging sensitive instruments.

Disinfection of Medical Equipment and Surfaces

Hospitals deploy this technology to sanitize devices like endoscopes between procedures. Critical tools requiring rapid turnaround – surgical instruments, ultrasound probes – undergo thorough sterilization in minutes rather than hours. Emergency departments use mobile units to disinfect trauma bays after each patient.

Operating rooms benefit from automated systems that treat surfaces post-surgery. This approach eliminates 99.7% of microbes on equipment handles and monitoring screens. Studies show it reduces cross-contamination risks in ICUs by 42% compared to manual cleaning alone.

Use in Infection Prevention Programs

Healthcare settings integrate this method into multi-stage safety protocols. It complements chemical cleaners by addressing hard-to-reach areas in patient rooms. Key advantages include:

- 24/7 operation without staff exposure risks

- Destruction of antibiotic-resistant pathogens

- Zero residue on neonatal unit equipment

“Our infection rates dropped 35% after implementing UV-C in high-touch areas.”

Beyond hospitals, food processors use it to sanitize packaging lines. Pharmaceutical labs apply it to maintain sterile production environments. Water treatment plants leverage its power to eliminate waterborne pathogens without chlorine byproducts.

Safety Guidelines and Precautions for UV-C Use

Every powerful technology demands respect in its application. UV-C systems require strict protocols to balance their germ-killing power with human safety. Direct contact with these emissions poses serious health risks, making proper handling non-negotiable.

Shielding People From Harm

Never operate these devices without protective gear. Specialized goggles blocking 100% of UV-C rays prevent retinal damage. Full-coverage clothing and face shields protect skin from burns resembling severe sunburns. Facilities must implement motion sensors that automatically shut off systems when humans enter treatment areas.

Smart Installation and Care

Position devices where reflective surfaces won’t redirect energy. Monthly lamp tests ensure consistent output – dimming bulbs create false security. Follow manufacturer schedules for component replacements. One hospital audit found 23% of systems underperformed due to expired lamps.

“Proper maintenance reduces equipment failure risks by 78% compared to ad-hoc servicing.”

Train staff to recognize warning signs like erythema (skin redness). Post clear visual alerts in operational zones. Combine engineering controls with administrative policies for layered protection. Regular safety drills prepare teams for accidental exposure scenarios.

Practical Guide to Using UV Light for Disinfection

Ready to upgrade your cleaning routine? Proper technique ensures maximum germ-killing power from your tools. Follow these evidence-based methods to achieve consistent results.

Step-by-Step Instructions for Effective Use

Start by washing all surfaces. Remove visible dirt that might block the rays. Dry tools completely – moisture reduces effectiveness.

Position items in your device so every angle gets direct exposure. Close the lid or door before starting. Modern systems like UV Smart units finish in under two minutes.

Factors Influencing Disinfection Time and Efficiency

Surface cleanliness matters most. Even thin grease layers can shield pathogens. Device power output determines speed – check your model’s wattage.

Placement affects results. Overlapping objects create shadows where germs survive. Regular maintenance ensures bulbs work at full strength. A 2023 audit found expired lamps caused 23% of systems to underperform.

Pro tip: Combine this method with routine cleaning for layered protection. Track exposure times for different materials – plastics need longer cycles than metals. Always wear protective gear during operation.