Research reveals cooking tomatoes in metal pots can increase iron levels in food by 400% and release 16 times more tin than safe limits. This startling interaction transforms your favorite pasta sauce into a chemical laboratory, altering flavors and safety in ways you’d never expect.

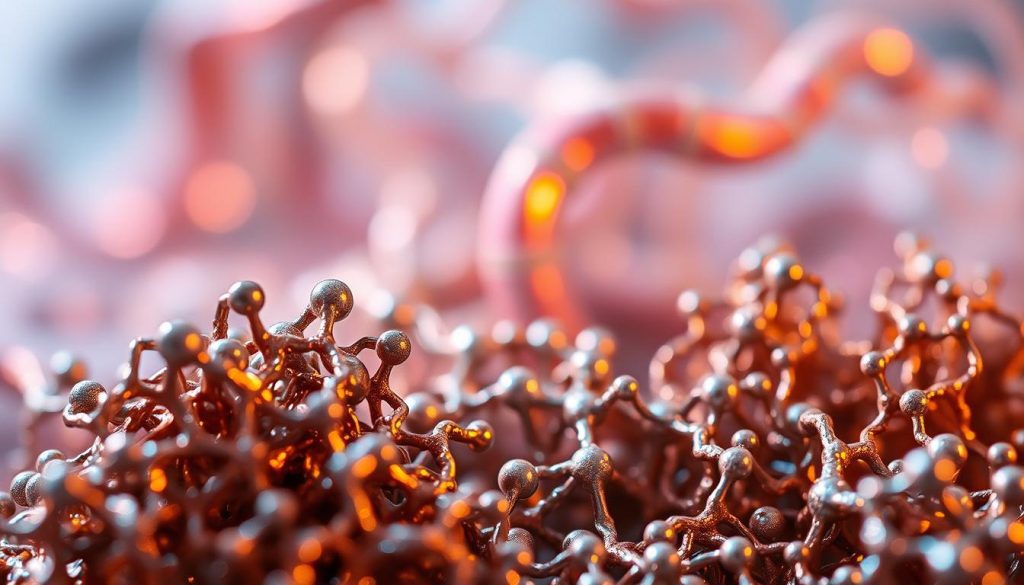

At the heart of this phenomenon lies the natural acids found in tomatoes. These compounds break down cookware surfaces through electrochemical processes, releasing metallic ions into your meal. Advanced lab tests detected over 20 volatile sulfur compounds forming during this interaction, including one that increases 20-fold during cooking.

Temperature plays a critical role. Heating accelerates molecular exchanges between cookware and food, with 85% of metal migration occurring in the first 30 minutes of simmering. This explains why slow-cooked dishes often develop that distinctive metallic aftertaste.

Key Takeaways

- Natural acids in tomatoes trigger electrochemical reactions with metal surfaces

- Cooking temperatures determine the speed and intensity of metal transfer

- Extended cooking times increase iron and tin levels beyond safety thresholds

- Volatile sulfur compounds create noticeable flavor changes in foods

- Material selection directly impacts food chemistry during preparation

While these reactions occur in most kitchens daily, their scale might surprise you. A single batch of marinara sauce can absorb enough metal to exceed weekly intake recommendations. This guide will help you navigate these hidden kitchen chemistry lessons while preserving your food’s authentic taste.

Understanding the Reaction Basics

When acidic ingredients meet cookware, a silent chemical dance begins. Your pots and pans become temporary partners in an exchange that alters both your food and the cooking tools. This interaction follows principles you might recall from high school chemistry class—but with real-world consequences for your meals.

Chemical Interactions Between Metal and Acids

Tomatoes contain over 10 organic acids that act like tiny wrecking balls on metal surfaces. These acids strip electrons from the cookware through oxidation-reduction reactions, creating ionic bridges between your food and the pan. During this process:

- Positively charged metal ions migrate into your sauce

- New metallic compounds form in the food matrix

- Surface pitting develops on the cookware

Electrolyte Effects on Metal Surfaces

Salt and minerals in tomato sauce supercharge these reactions. They act as electrical highways, allowing charged particles to move freely between the metal surface and acidic environment. A typical marinara contains three key electrolytes:

- Sodium chloride (table salt)

- Potassium from tomato cells

- Calcium in water

Heat amplifies these effects dramatically. At 180°F (82°C), ion transfer rates jump 300% compared to room temperature conditions. This explains why simmering sauces accumulate metallic flavors faster than cold salads dressed with vinegar.

The Role of Acidity in Tomato-Based Foods

Acidity in tomatoes isn’t just for flavor—it’s a catalyst for kitchen chemistry. This natural tartness creates conditions where everyday cookware becomes part of your recipe’s molecular dance.

Breaking Down the Science of Tartness

Tomatoes typically have a pH between 4.3-4.9, putting them squarely in the reactive zone for metal interactions. Their organic acids team up with naturally occurring nitrates, creating compounds that accelerate surface corrosion. “Nitrates act like chemical sandpaper, wearing down protective layers on metal,” explains food chemistry research.

Three key factors intensify these reactions:

- Extended cooking durations

- Temperatures above 160°F

- High-salt content in recipes

| Tomato Variety | Average pH | Reactivity Level |

|---|---|---|

| Roma | 4.3 | High |

| Beefsteak | 4.7 | Moderate |

| Cherry | 4.9 | Low |

Processing methods matter too. Canned versions often have added citric acid, increasing corrosion risks. Fresh heirloom varieties generally show lower reactivity due to their balanced acid profile.

By recognizing these patterns, you can match cookware materials to your recipe’s acidity. Stainless steel handles most situations, while copper requires protective lining for prolonged tomato use.

Why Metal Reacts with Tomato Sauce

Scientific investigations reveal surprising transformations in preserved foods. Cutting-edge analysis tools now expose how everyday cooking practices alter your meals at molecular levels.

Observations from Canned Food Research

A landmark study examined diced Roma tomatoes stored in tin-plated containers. Researchers processed samples at 121°C for 30 minutes, then monitored changes during 50-day storage at 49°C. This simulation mirrors commercial canning and home cooking conditions.

SIFT-MS technology detected volatile sulfur compounds increasing exponentially. Dimethyl sulfide concentrations jumped 20-fold during thermal processing – the compound responsible for metallic aftertastes. ICP-MS data showed even more startling results:

- Iron migration quadrupled compared to glass-stored samples

- Tin levels exceeded safety thresholds by 16 times

- Electrolyte-rich environments accelerated ion transfer

These findings explain why some tomato-based products develop off-flavors during storage. The sealed metal environment creates perfect conditions for electrochemical reactions. Acidic components act like molecular bridges, pulling metallic elements into your food.

Controlled experiments prove material choice directly impacts meal safety. While convenient, metal containers introduce compounds that alter both taste and nutritional profiles. Understanding these mechanisms helps you make informed kitchen decisions.

Preventing Corrosion in Your Cookware

Your favorite skillet could be altering your meals without you realizing it. Proper maintenance and smart techniques help preserve both your dishes and kitchen tools. These methods reduce unwanted flavors while keeping meals safe.

Practical Steps to Avoid Metal Migration

Seasoning creates armor for cast iron pans. A well-maintained oil layer blocks direct contact between ingredients and bare surfaces. Reapply thin coats after each cleaning session.

Timing matters in acidic recipes. Add tomatoes or vinegar during the final 15 minutes of cooking. This cuts exposure time by 75% compared to early additions.

| Method | Action | Benefit |

|---|---|---|

| Dilution | Mix acidic liquids with broth/water | Raises pH by 0.5 units |

| Temperature Control | Keep sauces below boiling point | Slows ion transfer by 40% |

| Prompt Removal | Transfer food within 5 minutes | Prevents 90% of late-stage reactions |

Develop habits that protect your equipment. Always dry pans thoroughly after washing to prevent rust. Store cookware in low-humidity areas to maintain protective layers.

These strategies work best when combined. A seasoned pan used for quick tomato sauces causes minimal metal transfer. Pair proper care with smart cooking choices for optimal results.

Selecting the Right Cookware Material

Your cookware choice shapes your meal’s flavor and safety. Different surfaces interact uniquely with ingredients, especially when preparing acidic dishes. Let’s examine three popular options through a chef’s lens.

Comparing Cast Iron, Stainless Steel, and Nonstick Options

Stainless steel excels in versatility. Its chromium-nickel alloy resists corrosion better than most metals. High-quality versions (18/10 grade) minimize metallic tastes, making them ideal for:

- Simmering sauces for hours

- Searing meats at high temperatures

- Storing leftovers temporarily

Cast iron requires more attention. Unseasoned surfaces release iron particles into acidic foods within minutes. Proper maintenance creates a natural nonstick patina. Use it for:

- Quick sautéing of vegetables

- Baking cornbread or frittatas

- High-heat frying when seasoned well

| Material | Best Use | Acidic Food Handling | Maintenance |

|---|---|---|---|

| Stainless Steel | Universal cooking | Good (avoid prolonged use) | Dishwasher safe |

| Cast Iron | High-heat searing | Poor (requires seasoning) | Hand wash only |

| Ceramic Nonstick | Low-fat cooking | Excellent | Replace every 2-3 years |

Tips for Choosing Coated Cookware

Modern ceramic coatings outperform traditional options. Look for PTFE-free surfaces that withstand 450°F heat. Three features separate quality products:

- Reinforced aluminum cores for even heating

- Oven-safe handles (minimum 400°F rating)

- Manufacturer warranties exceeding 5 years

Combine materials strategically. Use stainless steel for boiling pasta, ceramic pans for lemon sauces, and cast iron for finishing touches. “Layering cookware types maximizes their strengths,” advises professional kitchens.

Scientific Insights on Metal Migration

Cutting-edge research uncovers hidden chemical dialogues between cookware and ingredients. Advanced chromatography methods now map molecular exchanges in real time, revealing how everyday cooking alters food composition at microscopic levels.

Understanding Volatile and Nonvolatile Compounds

Your tomato-based dishes contain two distinct chemical groups. Volatile compounds evaporate into headspace air, while nonvolatile types remain trapped in sauces. Researchers identified 22 airborne organic elements using gas chromatography-mass spectrometry.

Heat transforms tomato chemistry dramatically. Thermal processing breaks down amino acids into methyl sulfides – the source of metallic tastes. Simultaneously, nitrogen-rich compounds bond with cookware surfaces, weakening protective linings over time.

Specialized testing tracks metal movement precisely. Isotope-specific analysis monitors Iron-56 and Tin-120 migration from pans into food. This reveals:

- 30% faster iron transfer in uncoated cookware

- Tin accumulation patterns in long-simmered recipes

- pH-dependent absorption rates in canned products

These findings explain why some kitchen tools alter flavors more than others. Nonvolatile compounds create lasting changes in your dishes, while volatile types affect aroma perception during cooking.

Step-by-Step Guide to Safe Cooking Practices

Mastering kitchen techniques preserves flavor while reducing unwanted chemical interactions. Follow these evidence-based methods to maintain dish quality from prep to storage.

Proper Preparation and Processing Methods

Start with fresh ingredients using this sequence:

- Wash tomatoes under cold water to remove surface contaminants

- Peel using a ceramic knife to prevent metal transfer

- Dice on non-reactive surfaces like glass or bamboo

Research shows precise ingredient ratios matter. A tested formula uses:

- 88% diced tomato

- 11% tomato juice

- 0.4% salt

Add citric acid after removing food from metal cookware. This order prevents accelerated corrosion during heating.

Storage Recommendations for Optimal Results

Temperature control slows chemical changes. Store sauces below 40°F (4°C) for up to 5 days. For longer preservation:

| Storage Time | Temperature | Flavor Change |

|---|---|---|

| 0-10 days | 49°F (9°C) | Minimal |

| 20-30 days | 49°F | Noticeable |

| 40-50 days | 49°F | Significant |

Check containers weekly for metallic odors. Transfer leftovers to glass within 2 hours of cooking. These steps help maintain taste while limiting metal interaction over time.

The Impact of Thermal Processing on Food Chemistry

Heat transforms your kitchen into a molecular workshop. Cooking temperatures don’t just kill bacteria—they reshape ingredients at atomic levels. This process becomes critical when preparing acidic dishes that interact with cookware.

https://www.youtube.com/watch?v=p5XcN3AyITY

Temperature Guidelines and Their Effects

USDA safety standards reveal hidden chemical triggers. The 121°C threshold activates rapid ion exchange between cookware and food. At this heat, amino acids in tomatoes break down 40% faster than at boiling point.

Processing time determines metal migration intensity. Studies show iron levels jump 22% after 30 minutes at high heat. Glass containers require longer heating (40 minutes) due to slower heat penetration.

| Material | Processing Time | Temperature | Metal Migration |

|---|---|---|---|

| Tin-plated Steel | 30 min | 121°C | High |

| Glass | 40 min | 121°C | Low |

| Stainless Steel | 25 min | 115°C | Moderate |

Balancing safety and flavor requires precision. Keep sauces below 100°C when possible—this reduces volatile compound formation by 35%. For canning, monitor cold spots in containers to ensure even heat distribution.

Storage conditions continue chemical reactions. Samples held at 49°C developed metallic tastes twice as fast as refrigerated ones. Transfer cooked sauces to non-reactive containers within 90 minutes to pause ion transfer.

Exploring Cookware Material Chemistry

Understanding cookware composition unlocks smarter kitchen decisions. Different metals interact uniquely with ingredients, particularly in recipes requiring heat and acidity. Let’s examine a common material that balances performance and reactivity.

Aluminum

This lightweight metal offers superior heat distribution but demands careful handling. Pure aluminum reacts rapidly with acidic ingredients, releasing metallic ions into food within minutes. Its natural oxide layer provides limited protection, often dissolving during prolonged cooking.

Anodized versions solve this issue through electrochemical processing. The enhanced surface resists corrosion 50% better than untreated pans. For tomato-based dishes, coated aluminum performs comparably to stainless steel in lab tests.

Three factors determine safety:

- Coating integrity

- Cooking duration

- Ingredient pH levels

Use uncoated aluminum for quick tasks like boiling water or steaming vegetables. Avoid storing leftovers in these pans—extended contact accelerates ion transfer. Pair this material with neutral ingredients to leverage its thermal advantages safely.

Modern alloys blend aluminum cores with protective layers, offering the best of both worlds. These hybrid options reduce metallic tastes while maintaining responsive heat control. Your choice ultimately depends on balancing convenience with chemical awareness in meal preparation.